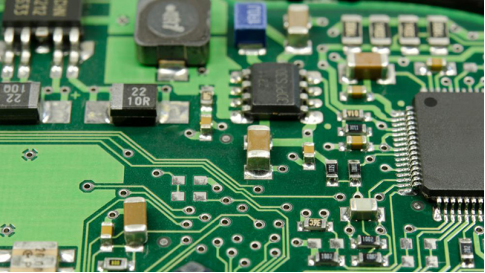

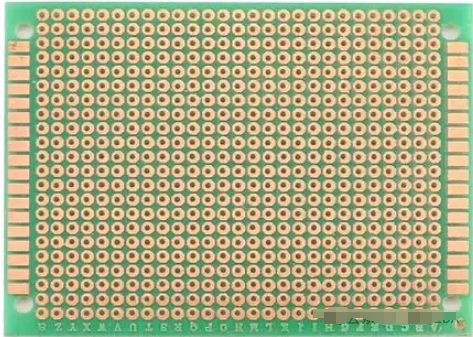

Let ’ s continue to learn about the last two types of holes found on HDI PCB.

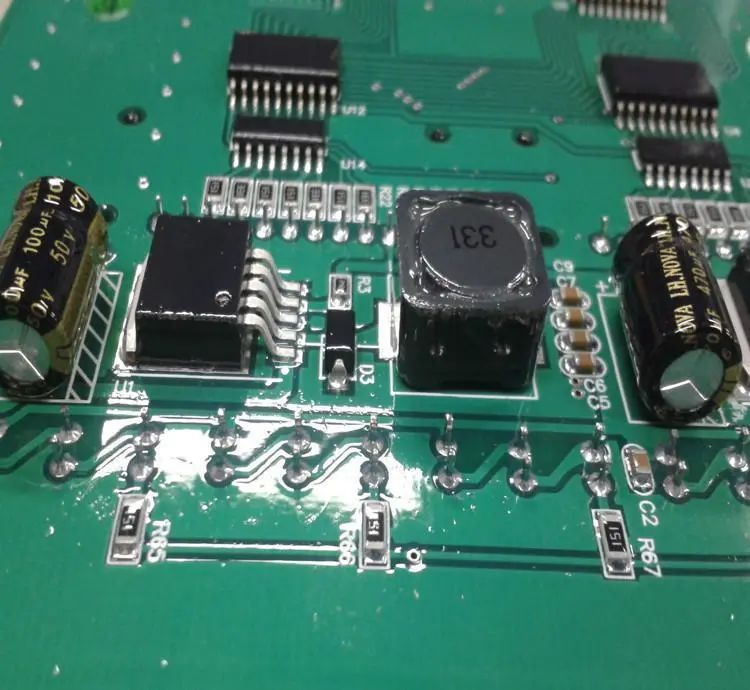

1. Plated Through Hole

Plated Through Hole s are internally tin-plated holes, such as via s and plated through-holes for insertion of component leads. These holes have a metal connection in the middle of the hole wall to connect the TOP and BOTTOM layers. During soldering, solder can also flow into the hole to enhance the strength of the solder joint.

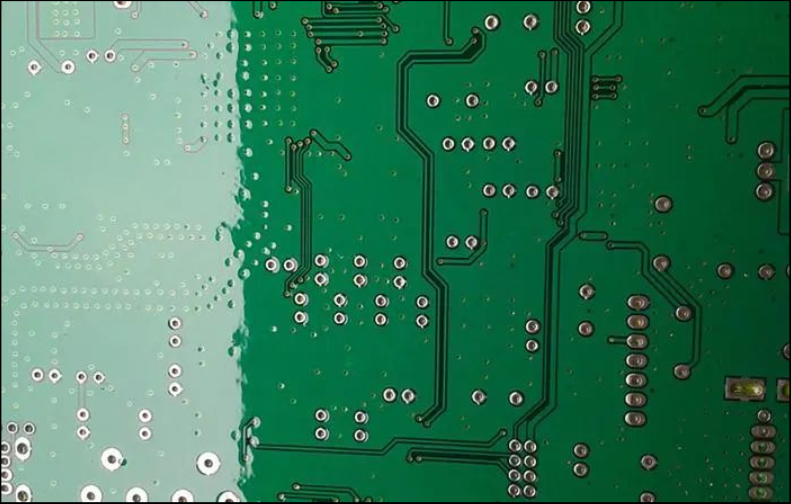

2. No- Plated Through Hole

NPTH (Non-Plated Through Hole) holes are holes that are not tin-plated internally and are typically used for alignment purposes. Since they do not require soldering, no pad is retained. However, the processing requirements for NPTH holes are much higher than for PTH holes. For example, if a PTH hole with a designed diameter of 1.0mm is made using a 1.0mm drill bit, it might actually create a 1.05mm hole, which, after internal tin plating, results in a hole diameter of exactly 1.0mm.

NPTH holes, on the other hand, cannot be plated. If the hole is drilled too large, the entire PCB becomes unusable. It is necessary to consider the plating of the hole in advance. Additionally, NPTH holes do not have pads, so if the drilling is off-center, it can easily cut into adjacent traces. Therefore, NPTH holes generally require a 0.25mm no-routing space around them. PTH holes, which have pads, do not need to consider the risk of drilling off-center.

So those are all kinds of holes we usually using on HDI PCB, if you want to learn more about them, you ask our sales while you हमारे साथ ऑर्डर ले रहे हैं.

हिन्दी

हिन्दी English

English Español

Español Português

Português русский

русский français

français 日本語

日本語 Deutsch

Deutsch Tiếng Việt

Tiếng Việt Italiano

Italiano Nederlands

Nederlands ไทย

ไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা

বাংলা Dansk

Dansk Suomi

Suomi Pilipino

Pilipino Türk

Türk Gaeilge

Gaeilge عربى

عربى Indonesia

Indonesia norsk

norsk اردو

اردو čeština

čeština Ελληνικά

Ελληνικά Українська

Українська Javanese

Javanese فارسی

فارسی தமிழ்

தமிழ் తెలుగు

తెలుగు नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine Қазақ

Қазақ Euskal

Euskal Azərbaycan

Azərbaycan slovenský

slovenský Македонски

Македонски Lietuvos

Lietuvos Eesti Keel

Eesti Keel Română

Română Slovenski

Slovenski मराठी

मराठी Српски

Српски 简体中文

简体中文 Esperanto

Esperanto Afrikaans

Afrikaans Català

Català עִברִית

עִברִית Cymraeg

Cymraeg Galego

Galego 繁体中文

繁体中文 Latvietis

Latvietis icelandic

icelandic יידיש

יידיש Беларус

Беларус Hrvatski

Hrvatski Kreyòl ayisyen

Kreyòl ayisyen Shqiptar

Shqiptar Malti

Malti lugha ya Kiswahili

lugha ya Kiswahili አማርኛ

አማርኛ Bosanski

Bosanski Frysk

Frysk ជនជាតិខ្មែរ

ជនជាតិខ្មែរ ქართული

ქართული ગુજરાતી

ગુજરાતી Hausa

Hausa Кыргыз тили

Кыргыз тили ಕನ್ನಡ

ಕನ್ನಡ Corsa

Corsa Kurdî

Kurdî മലയാളം

മലയാളം Maori

Maori Монгол хэл

Монгол хэл Hmong

Hmong IsiXhosa

IsiXhosa Zulu

Zulu Punjabi

Punjabi پښتو

پښتو Chichewa

Chichewa Samoa

Samoa Sesotho

Sesotho සිංහල

සිංහල Gàidhlig

Gàidhlig Cebuano

Cebuano Somali

Somali Точик

Точик O'zbek

O'zbek Hawaiian

Hawaiian سنڌي

سنڌي Shinra

Shinra հայերեն

հայերեն Igbo

Igbo Sundanese

Sundanese Lëtzebuergesch

Lëtzebuergesch Malagasy

Malagasy Yoruba

Yoruba